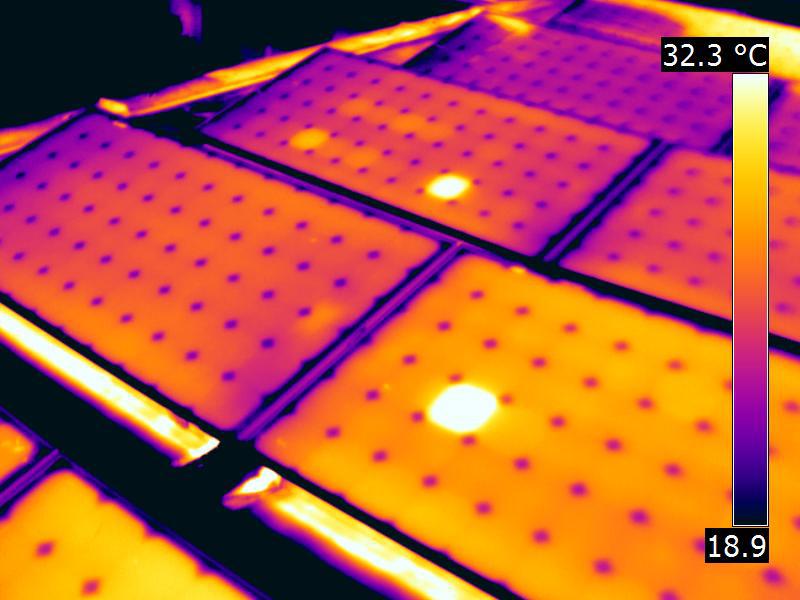

Aerial Imaging / Hotspot Detection

Using drones to conduct thermal and visual inspections of solar panels found on utility-scale installations can identify defects or solar panels or strings or groups that may be offline. An aerial inspection can identify when strings, solar panels, and sections are offline because inverters not running.

Imaging often identifies broken modules or hot spots on modules.

Aerial inspections enable you to

- Identify, document, and diagnose panel degradation

- Scan inverters and data capture vegetation management.

- Register modules output

- Make a warranty claim

- Drones can survey an entire solar farm to identify faults in a fraction of the time and expense.